Secondary Members

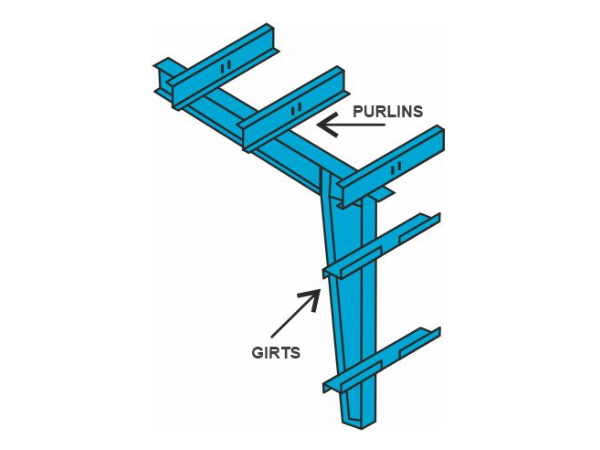

Secondary Members - Purlins, Girts, and Struts

Secondary members, such as purlins, girts, and struts, play a vital role in the construction of pre-engineered buildings (PEBs). These members are essential for providing support to the roof and wall panels, enhancing the structural stability and overall integrity of the building.

Purlins are horizontal structural members that run along the length of the roof, supporting the roof panels and transferring the load to the primary framing system. They are typically installed at right angles to the main frames and are designed to resist the loads imposed by the roof system, including dead loads, live loads, and wind loads.

Girts, on the other hand, are horizontal members that are installed along the length of the walls, providing support to the wall panels. They help distribute the lateral loads acting on the walls, enhance the rigidity of the structure, and resist the wind loads and other applied forces.

Struts are diagonal members used to reinforce the structural stability of the PEB system. They are typically installed at various locations within the building, such as roof truss intersections or wall corners, to resist compressive or tensile forces and prevent buckling.

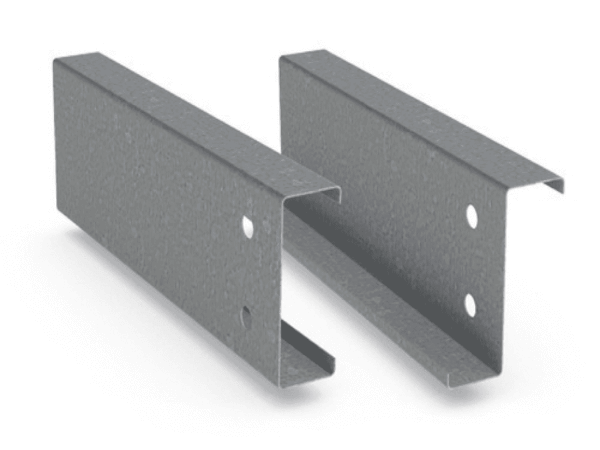

Purlins, Girts, and Struts in PEBs are commonly made of two types of materials: Galvanized Iron (GI) and Mild Steel (MS)

Galvanized Iron (GI)

GI refers to steel that has been coated with a layer of zinc to protect it from corrosion, making it suitable for applications where moisture or harsh weather conditions are a concern. GI purlins, girts, and struts are commonly used in PEBs due to their corrosion resistance properties.

Mild Steel (MS)

MS refers to regular steel without any protective coating. MS purlins, girts, and struts are also used in PEBs, particularly when the building is located in a relatively dry environment or when additional protective measures, such as paint or coatings, are applied to prevent corrosion.